The rubber extrusion process is a technology developed in the early 20th century. Since then, this process has become a widely used and versatile method for creating various rubber products. Silicone rubber extrusion is also one of the most popular extrusion processes in the world industries. Different types of silicone weather stripping, gaskets, and tubing are noteworthy examples. These products are increasingly popular due to their unique properties. As a result, they are an ideal choice for a wide range of applications.

Silicone door seal prevents leaks from sealing doors and windows. Their unique properties made them suitable for many different industries. They are famous for their excellent durability, flexibility, and resistance to environmental factors.

This article will comprehensively guide you with the silicone rubber extrusion fundamentals. We will discuss the advantages and limitations of using silicone seal strips. In addition, we will also explore different types of seals available and popular silicone rubber seal strips in the market. In the end, this article will provide expert advice on selecting the right silicone rubber products for your project.

What is a silicone rubber extrusion?

Silicone rubber extrusion is a manufacturing process used to create various rubber products. Rubber seal strips, tubes, profiles, and sheets are noteworthy examples. The silicone rubber extrusion process forces a silicone rubber compound through a die or mold. These dies, or molds, come with a specific shape to create a product with a consistent cross-sectional profile.

The process begins by heating the silicone rubber compound. Later it is fed into an extruder that uses a specialized screw to push these compounds through a die. Later, these hot rubber compounds get the desired shape and size. Finally, the process cools and cuts this continuous profile to the desired length.

Silicone rubber profiles can withstand high temperatures as high as 200 degrees Celsius. These profiles can also work in refrigeration and freezer unit applications. Silicone weather stripping is also resistant to chemicals, UV, and ozone. It also helps in electrical insulation.

Silicone rubber extrusion has many applications due to its versatility and durability. One of the most common applications is manufacturing seal strips and gaskets for various industries. Silicone rubber seals are the first choice in mechanical, industrial, and electrical applications. However, silicone rubber extrusion also creates tubing for medical and food processing applications.

Why use silicone rubber seals?

Due to its unique properties, silicone rubber is popular in various industries. This section will evaluate the reasons behind this material’s popularity. Silicone rubber seals offer numerous benefits that make them suitable for multiple applications. Let’s look at some facts that make them a popular choice.

- Temperature resistance: Silicone rubber seals can withstand various temperature ranges. It can work in both high and low-temperature applications. The nominal temperature ranges from -60°C to 200°C.

- Chemical resistance: Silicone rubber seals are highly resistant to chemicals. It can work with oils, fuels, and solvents. Besides, food-grade silicone rubber products are also popular in food processing industries.

- Weather resistance: Silicone rubber seals have excellent weather resistance characteristics. They can withstand UV radiation, ozone, and extreme weather conditions. As a result, they are ideal for outdoor applications.

- Compression set resistance: Silicone rubber seals have excellent compression set resistance. In this case, rubber seals can maintain their shape and properties over extended compression periods. As a result, silicone door seal strip is ideal for applications such as door and window seals.

- Versatility: Silicone rubber seals come in various shapes and sizes. As a result, they became suitable for multiple applications. They are commonly used in mechanical, industrial, and electrical applications.

- Durability: Silicone rubber seals have excellent durability. As a result, they became suitable for applications requiring long-lasting seals. It also ensures that these seals can withstand harsh conditions and are ideal for repeated use.

- Electrical insulation: Silicone rubber seals also offer excellent electrical insulation properties. As a result, they are also popular in electrical applications.

Limitations of silicone rubber seals

As the previous section shows, silicone rubber extrusion profiles offer many advantages. Still, they have some limitations. You should consider these points while choosing material for your project. Some factors may affect the performance of silicone rubber seals. Temperature, humidity, and pressure are important topics we should discuss here.

Silicone rubber seals can withstand a wide range of temperatures. Yet, extreme temperatures can still affect their performance. On the other hand, high humidity and pressure can also impact their effectiveness. Therefore, you should choose the seal based on your application’s requirements.

Silicone rubber seals offer many benefits compared to other sealing materials. Although, they may not always be the best choice for every application. Concerning this point, let’s consider the application of EPDM, neoprene, and PVC seals. EPDM seals have superior weather resistance capabilities. As a result, they are more suitable for outdoor applications. On the other hand, neoprene seals are better for oil and chemical processing applications. Moreover, PVC seals are ideal for their affordability and ease of installation.

In specific applications, silicone rubber seals may not adhere to some surfaces. Besides, these silicone products may not be suitable for low compression set resistance. Moreover, some silicone rubber seals can not withstand some chemicals.

Types of silicone rubber seals

Silicone extrusion products may come in a variety of forms. You can customize these products to fit various applications. However, there are three primary types of silicone rubber extrusion products. Silicone rubber profiles, tubing, and sheets & gaskets are noteworthy.

- Silicone rubber profiles: These are the most popular silicone rubber extrusion products. They come in various shapes and sizes, including round, rectangular, square, and other complex shapes. These rubber profiles are ideal for weather stripping, edge trims, and sealing applications.

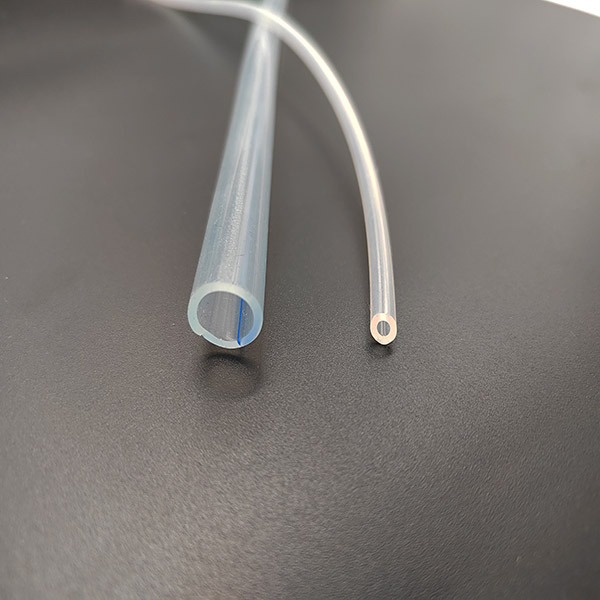

- Silicone rubber tubing: This seal is flexible and suitable for transferring fluids and gases. They may be found in medical devices, food processing equipment, and laboratory applications.

- Gaskets and sheets: These silicone rubber seals are prevalent in industrial applications. They are available in various thicknesses.

Popular Silicone rubber seal strips

Silicone rubber seals are versatile and applicable in a wide range of applications. They offer excellent durability, flexibility, and resistance to environmental factors. These products are widely used in the automotive, aerospace, construction, and manufacturing industries. Here are some popular silicone rubber extrusion products.

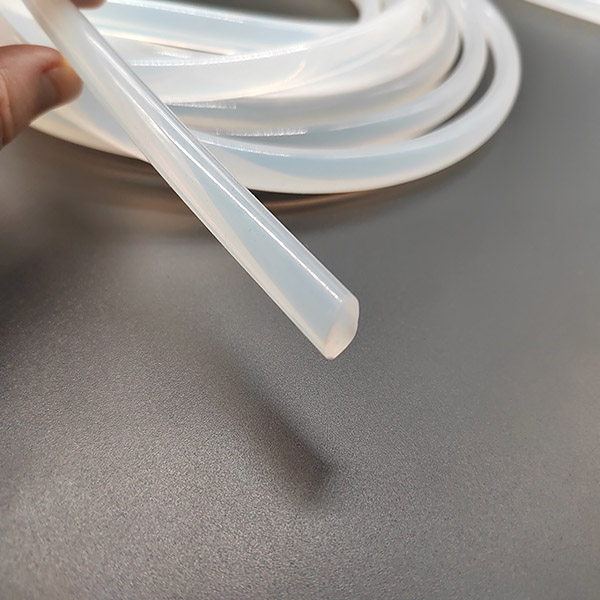

Silicone Rubber Strips

These extrusion products provide exceptional sealing, insulation, and flame-resistant characteristics. As a result, they are popular in electrical, construction, automotive, and aerospace applications. These rubber strips provide excellent resistance to temperatures ranging from -60°C to 230. These rubber seal strips are prevalent in sealing and insulating various environmental factors. For example: air, wind, dust, moisture, light, and noise.

Silicone Sponge Extrusions

Silicone sponge strips are made of soft, pliable, and flexible materials. They provide waterproof and airtight features. They can withstand high and low temperatures ranging from -60°C to 250. You may find different kinds of seal strips with a width and thickness ranging from 5mm to 150mm and 1mm to 50 mm, respectively.

Platinum Cured Silicone Rubber Cord

Platinum-cured silicone rubber cords are also known as addition-cure silicone cords. They are high-performance silicone products prevalent in medical, pharmaceutical, and food processing industries. In the manufacturing process of this product, platinum acts as a catalyst that produces cleaner and more stable products.

Platinum-cured silicone rubber cords are also famous for their flexibility and durability. They are bio-compatible and non-toxic, making them suitable for medical and pharmaceutical applications. Platinum-cured silicone rubber cords may have different cross-section areas based on various applications.

Platinum Cured Silicone Tubing

Like the platinum-cured silicone rubber cord, silicone tubing is prevalent in many industries. You may find these silicone tubing in the bio-pharmaceutical, medical, food, and beverage industries. They offer high-degree purity, peroxide-free, and better tensile and tear strength properties. You can also customize the dimension based on the specific requirements of applications.

Silicone Foam Tube

It is a closed-cell elastomer product that provides excellent sealing and insulating resistance. Various sizes are available in the Seashore Rubber factory. The inner and outer dimension ranges from 2mm to 60mm and 6mm to 80mm, respectively. Silicone foam tubes also offer cross-section areas, such as rectangular and irregular types.

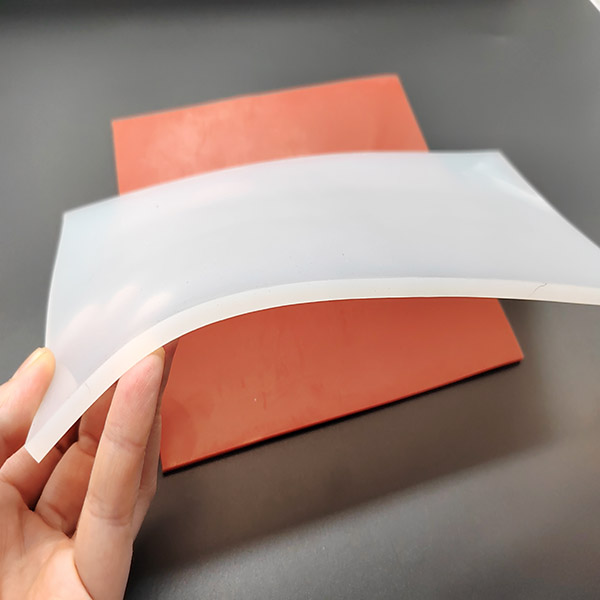

Silicone Rubber Sheets

They are flat and flexible sheets made from silicone rubber. They are available in a range of thicknesses, colors, and hardness. Silicone sheets have a variety of uses in different industries. Oven seals, food processing, electrical insulation, and marine are special applications.

Expert Advice

Silicone rubber extrusion products play a vital role in the mechanisms of different applications. Therefore, choosing the right products is necessary to ensure optimal performance and longevity of the seal. First, what you should look for is the temperature requirement. In this case, choose rubber seal strips that suit the needs of your application.

Next, you should consider the type of chemicals your rubber seals will deal with. In addition, you should also check the compatibility of your system’s compression set and the chosen rubber seals. Besides, consider the tensile strength, durometer, and color of the product.

Above all, you can find a wide range of rubber products at Seashore Rubber Factory. Navigate to the links attached to each of the products. You can learn more about those products on those products’ pages. Besides, if you have any questions regarding the rubber seal and gasket, contact this supplier. They keep one of the best customer service teams for visitors and customers.